Description

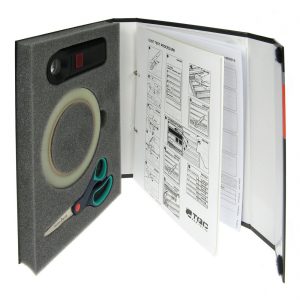

QNix® 5500

QNix® 5500 is recommended in heavy corrosion protection, industrial coating and in vehicle evaluation

The QNix® 5500 product range contains an integrated and a modular system.

The integrated system has a permanently installed probe which cannot be removed. It is not possible to change the probe or to connect the handheld with an adaptor cable.

The modular device enables you to take the probe off the handheld, thus to change the probe or to connect the adaptor cable. The probe range of the modular device is wider.

Tip: The integrated device can be identified with its black probe cover, the modular device has a grey probe holder.

The probe range of the modular device is wider.

QNix® 5500 The coating thickness gauge

QNix® 5500 with integrated or with changeable

probe

Safety by precision and trueness

For valid results in quality assurance

• High measuring trueness over the entire range

• High repeatability of measured results

• Temperature compensation directly

in the sensor

Time saving by ergonomics

Fast working progress for fatigue-proof

continuous use

• Luminosity IPS-LCD, 2“, colour, 350 cd/m2,

reading angle 70°

• Automatic flip display 0°, 90°, 180°, 270°

• Low centre of gravity with large contact surface

for precise measuring

QNix® 5500 changeable probes modular – robust – flexible

All exchangeable standard probes of the QNix® 5500 can also be used

in the new QNix® 9500. QNix® thus ensures the flexibility and compatibility

of the new probes which are interchangeable between both models.

Technical data QNix® probes

Technical measurements

Status display with RGB-LED on the probe yes

Measuring principle magnetic: magnetic field amendment / hall-effect Fe / whirl current NFe

Standards DIN EN ISO 2808, DIN 50981, DIN 50984, ISO 2178,

BS 5411 (3 & 11), BS 3900-C5, ASTM B 499, ISO 2360,

ASTM D 1400, ASTM D 1186, ASTM D 7091

Measuring range depending on the probe

Measuring speed (measurements per minute) ≥ 120

Accuracy of measurement on Fe substrates related to

QNix® reference standards

Accuracy of measurement on NFe substrates related to

QNix® reference standards

± (1 μm + 2 % of the reading) to 2,0 mm

± 3 % of the reading from 2,0 mm

± (2 μm + 2 % of the reading) to 2,0 mm

± 3 % of the reading from 2,0 mm

Smallest measuring surface Fe / NFe diameter 14,5 mm

Smallest curvature konvex Fe

Smallest curvature konvex NFe

6 mm – Zero point adjustment on original substrate (accuracy checked up to 250 μm)

50 mm – Zero point adjustment on original substrate (accuracy checked up to 250 μm)

MInimum thickness of base metal Fe

MInimum thickness of base metal NFe

100 μm – Zero point adjustment on original substrate (accuracy checked up to 250 μm)

50 μm – Zero point adjustment on original substrate (accuracy checked up to 250 μm)

Mechanical properties

Material casing top* Stainless steel V4A (1.4305)

Material casing bottom* Trogamid® (CX7323)

Material measuring tip* Ruby, polished (Al203)

Dimensions (height, diameter) 34,5 mm, 14,5 mm

Weight 11,9 g

Robustness / environmental conditions

Classification

IP protection IP65

Operating temperature -20 °C to +70 °C

Storage temperature -20 °C to +70 °C

Max. surface temperature 80 °C

Max. surface temperature at 1s measuring time every 20s 100 °C

* Clean with a damp cloth; chemically resistant against acetone (except soft rubber parts e.g. keyboards or rubber protective frame),

nitro dilution and ethanol