Description

While can coating the time-temperature cycle must be controlled carefully – Together with the cans the oven recorder winds through the conveying system in the oven and makes up a complete temperature profile. With help of paint cure specifications it determines the curing process by calculating the cure index for you, enabling a simple pass / fail setup. From a computer, you can analyse all gathered data with TQC Ideal Finish Analysis software and print a report with all measurement data and graphs.

Item No: CSTCX3040

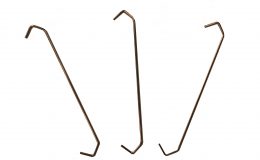

4-Channels

The CurveX 3 Nano has four thermocouple type K inputs to be used to measure either surface- or air temperature. The CurveX 3 Nano comes complete with 4 wire probes and self-adhesive attachment pads to position the probes. Each probe can be used for either surface or air temperature. The probes are usually attached to a real can on the next pin.

Housing

The CurveX 3 Nano is built into a stainless steel casing and has a can shaped form factor. This form factor allows the data logger to be used in a variety of can oven setups. Usually the cans traverse through the production process by placing them over pins, the pins in turn are attached to a big chain that runs through the whole production line. The housing at the same time functions as insulation box. Unlike our other CurveX products the Nano does not need a separate insulation box.

Inside end-caps

Typically the cans are painted both on the in- and outside. This is done in 2 different production processes. The CurveX can be used in both of these processes. During the first step, painting the inside, the cans are placed in trays that traverse through the first oven. The Nano is supplied with end-caps that allow the data logger to be placed in the tray. With these end-caps the data logger is completely cylindrical in shape.

Outside end-caps

To allow for easy installation into the production line and to reduce down time to a minimum, the CurveX 3 Nano has a special set of end-caps with adjustable fittings. These end-caps allow the data logger to be slided over a pin. Once in place, the position on the pin can be quickly fixed with 2 butterfly bolts.

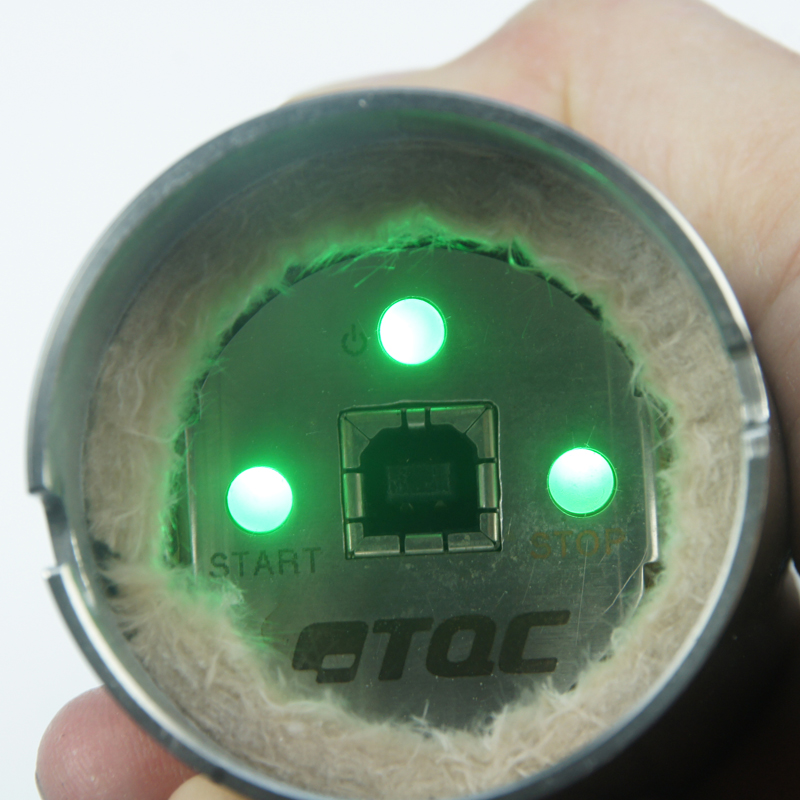

Easy operation

Opposite of the thermocouple connector side you find the buttons to control the CurveX 3 Nano. The 3 buttons are: Power / Start and Stop. The buttons are integrated into the status LED’s, which indicate on/off or if the Nano is currently logging, etc. In between the LED buttons is the industrial type USB connector to read out all data with your PC and the Ideal Finish Analysis software.

More features

The housing is extremely durable and impact resistant. Features industrial type USB connectors. Rechargeable batteries. Complete paint library and Ideal Finish Analysis software support. Large memory and 10 different batches to store data. Factory calibrated.

Operate through only 3 buttons

Meaningful feedback of multi colored LED’s

Factory calibrated for immediate use

Downloads data through a standard USB port

Rechargeable battery pack through USB connector

Large memory of max. 160.000 readings

Memory for 10 different batches, automatically overwrites the oldest results

Programmable “paint type” memory for immediate “pass / fail” result

Round design, only 53 mm in diameter, for use in can ovens

Compatible with Ideal Finish Analysis software