Inspection of rubber linings

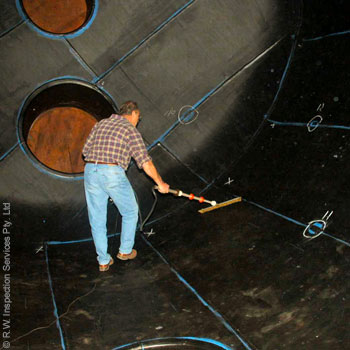

Rubber linings find a variety of applications within the framework of heavy duty corrosion protection. Even slightly conductive materials can be tested for defects or cracks with the ISOTEST® holiday detector.

Typical fields of application for rubber linings / coatings within the framework of heavy corrosion protection are flue gas desulfurization plants, swimming pools, waste incineration plants, waste water treatment, water desalination plants, the chemical, steel and mining industry as well as the power plant technology. Both rubber linings in the factory as well as on a construction site have to go through a final inspection according to DIN EN 14879 (ex DIN 28055). Also here, porosity testing is normatively required. Thanks to our close cooperation with industry leaders in the field of corrosion protection the ISOTEST® holiday detector and related accessories are continuously optimized and adapted to changing requirements. Therefore they guarantee efficient corrosion protection on the highest level.

ISOTEST Rubber Lining Test Kit

Part-no.: 0113510020

Scope of supply:

- ISOTEST inspect 35 instrument complete with high voltage inspection probe including safety button

- Instrument bag with shoulder strap

- Rechargeable battery, 6V / 4.5 Ah (VLRA) – easy to change in its own compartment

- Charger for ELMED Pb-accumulator 100-240 V/50 Hz

- Grounding cable 10 m with clip and instrument plug

- Grounding cable 15 m with two clamping jaws

- Spare battery for safety button and fuse for rechargeable battery

- Flat brush electrode with angle adjustment, length 400 mm, brass

- Wire rake electrode, trim length 200 mm, stainless steel

- Extension bar 500 mm with electrode chuck

- Aluminium transportation box for ISOTEST and accessories

- Works and calibration certificate