Description

When viscosity testing is useful

Viscosity testing is absolutely essential if you want to be confident that your paints, inks, varnishes and coatings stay in one place! Over time, deformation or flow can have a disastrous effect on the appearance of products or packaging.

Measuring viscosity during the test and inspect process allows you to choose the right materials for the job – so your surfaces look as good as they are supposed to all the way from production to final destination.

When viscosity testing is useful

Measuring the viscosity of a sample lets you know how much force is required to move it. This lets you know how resistant it is to flow – information that is very useful in a variety of applications.

For example, it can tell you whether the ink on a piece of packaging is likely to run or be smudged during shipping, or it can be used to work out whether sauce will pour from a bottle at the required speed. It can even be used to determine whether an adhesive will perform properly over time.

Measuring the viscosity of inks and coatings that are used to coat industrial machinery or car parts can also have huge safety and efficiency ramifications, as the integrity of a coating can affect the smooth running of machinery.

Due to its huge range of applications, viscosity testing is used across many different industries – from food and beverage to flexible packaging.

Viscosity testing: the materials

Viscosity testing is recommended for materials like inks, paints, varnishes and coatings or organic or inorganic surfaces. It can also be used to test everything from foods and beverages to chemicals or adhesives. There are a variety of different testing methods that can be used to test different kinds of samples.

Most popular viscosity testing methods

There are five main ways of testing viscosity, they are:

- The rotational viscometer method

Often used in production labs and as part of a solid quality control process, this method measures the torque needed to turn an object that’s been placed in the sample fluid being tested. The measurement shows the sample’s viscosity.

- The capillary viscometer method

This is one of the earliest methods of measuring viscosity, first developed in 1800s. It measures the time it takes for a volume of liquid to mass through the length of a capillary tube. These were known as Ostwald or Ubbelohde viscometers.

- The falling sphere viscometer method

This method determines viscosity by dropping a sphere of a known density through a sample liquid and measuring how long it takes to fall. A similar process can be achieved using a falling piston.

- The vibrational viscometer meter method

An oscillating electromechanical resonator is immersed in the fluid sample and it measures the degree of damping the fluid offers, making it possible to work out the viscosity.

- The viscosity cups method

This is a relatively straightforward method that involves putting the sample in a container with a hole in the bottom then measuring the time it takes to fill a cup placed below it. Each cup design is unique and the Ford and Zahn cups are some of the most commonly used.

For help making sure you are choosing the right cups for your viscosity testing or to see the viscosity rating of calibration oils at a glance, be sure to check out our handy viscosity conversion chart.

Measure viscosity with Industrial Physics

Our engineers have almost 100 years of experience in the test and inspect field, which helps us source some of the best and most reliable testing machines and solutions. Some of our recommended machines are:

This modern testing machine is based on the popular traditional KREBS method, using a weight-driven rotating paddle to sense the paint viscosity at a constant 200 rpm. The torque induced is proportional to the viscosity of the sample and may be converted into viscosity (cP) or weight units (gms).

Sheen Cone and Plate Viscometer

Using high precision microprocessor controls, this machine is both fast and accurate. It has a temperature control plate, allowing you to test viscosity anywhere between 5°C and 65°C and it tightly controls the shear rate applied to 10,000S-1 (B.S./ ISO requirements) or to 12,000S-1 (ASTM).

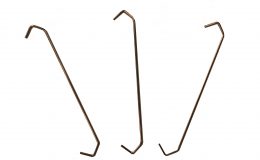

A flexible, two-in-one instrument that gives you a very high level of control during the viscosity reduction process whilst also providing very useful stability analysis. It has three different spindles available, one plate and two ball spindles, offering three different measuring ranges up to a maximum of 350 poise.

For our full range of viscosity testing machines, as well as accessories such as cups, oils and gels, be sure to check out our viscosity measuring equipment.

To find out more about our viscosity testing solutions, have a look at our evolution of inks and coatings guidebook.

Measure viscosity as part of a thorough test and inspect solution

Our global network of test and inspect specialists have knowledge of the kind of regulations, stipulations and testing requirements across international market and we have customers in 75 countries.

If you’re looking for advice or help choosing the right viscosity testing methods and machines, we’re the team for the job. To discuss how we could work with you to find a full and supported solution for all your testing needs, get in touch.